CONTACT US

TECHNOLOGY

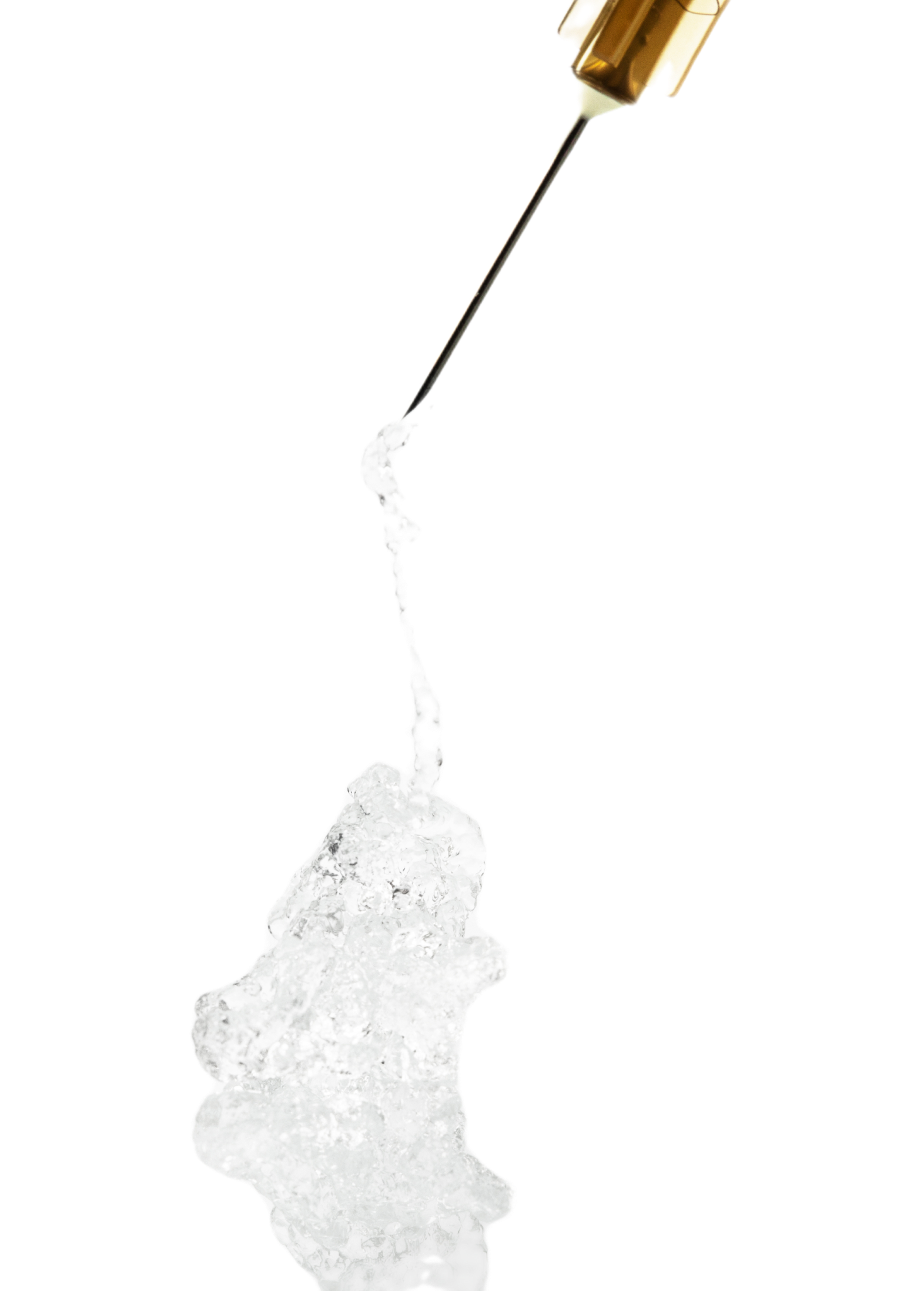

Pharmaceutical Purity Standard

PRODUCTION PROCESS

Selection of highly purified hyaluronic acid, European Pharmacopoeia Grade

Dissolution in NaOH. Obtaining HA with a certain molecular weight and its polydispersity

A special mechanism of thermal shift of the mixed polymerization reaction rate

Exposure to different temperature within a given amount of time, followed by ultraviolet irradiation of the gel. Thus there is formation of new intermolecular bonds

Dense elastic gel structure with "natural crosslinkings" which were obtained without chemical modifications Meso Extra Prefiller + a minimum amount of BDDE in comparison with standard technologies = SkinElly Fillers

TECHNOLOGY

Pharmaceutical Purity Standard

PRODUCTION PROCESS

Selection of highly purified hyaluronic acid, European Pharmacopoeia Grade

Dissolution in NaOH. Obtaining HA with a certain molecular weight and its polydispersity

A special mechanism of thermal shift of the mixed polymerization reaction rate

Exposure to different temperature within a given amount of time, followed by ultraviolet irradiation of the gel; thus there is formation of new intermolecular bonds

Dense elastic gel structure with "natural crosslinkings" which were obtained without chemical modifications Meso Extra Prefiller + a minimum amount of BDDE in comparison with standard technologies = SkinElly Fillers

Pharmaceutical purity standard: all SkinElly products are quality controlled according to the pharmacopoeia. During the production process, the raw materials undergo repeated quality control and a high degree of purification. All SkinElly products contain components of natural origin, fully biocompatible with the skin and fully resorbable.

SkinElly gels have a perfect balance between native and stabilized hyaluronic acid, which gives each product unique properties. Each product in the SkinElly line has been developed with specific correction goals and objectives. Our smart cross-linking technology preserves the dynamic long chains of hyaluronic acid. By helping to slow down the biodegradation of HA, we obtain the maximum stabilization factor for the desired product density and dynamic structure, but with a minimum amount of cross-linking agent and less rigid cross-links than standard modified hyaluronic acid technologies.

SkinElly gels have a perfect balance between native and stabilized hyaluronic acid, which gives each product unique properties. Each product in the SkinElly line has been developed with specific correction goals and objectives. Our smart cross-linking technology preserves the dynamic long chains of hyaluronic acid. By helping to slow down the biodegradation of HA, we obtain the maximum stabilization factor for the desired product density and dynamic structure, but with a minimum amount of cross-linking agent and less rigid cross-links than standard modified hyaluronic acid technologies.

→